10000lph Seawater Desalination Machine Is Used for High Salt Alkali Area and Seashore Area

Basic Info.

| Productivity | 10000L/H |

| Recovery Rate | 60-75% |

| RO Membrane Brand | Vontron |

| Water Pump | Cnp or Other |

| Frame Structure | Stainless Steel 304/316 |

| Function | Water Purification |

| Transport Package | Packed in Carton Case |

| Specification | CK-SW RO-10T |

| Trademark | CHUNKE |

| Origin | Guangdong, China (Mainland) |

| HS Code | 8421999000 |

| Production Capacity | 1000 PCS Per Year |

Product Description

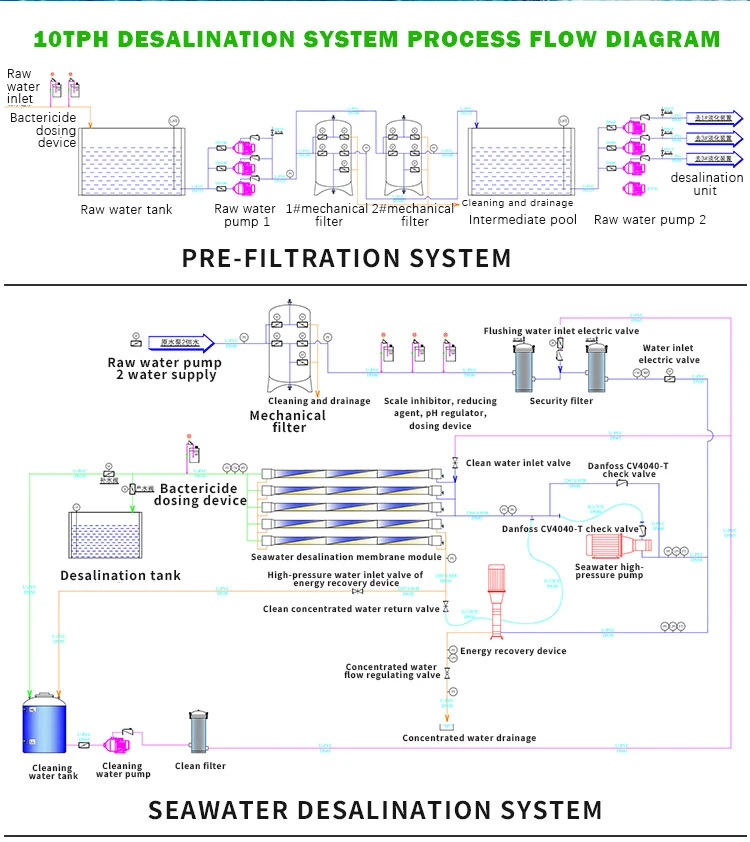

10000lph seawater desalination machine is used for high salt alkali area and seashore area

Chunke Reverse Osmosis water treatment system can be customized as regards to application. Some industry need very high grade purity for permeate water.Our solution for high grade purity double pass ro system and if it is necessary electrodeionization water treatment system.

Double Pass RO system has pretreatment section, raw water first enter the pretreatment than goes to ro membrane, at first pass we get pure water called as permeate and concentrated water. To reduce TDS more, we send first pass permeate to second ro membrane and water becomes more pure.

Industrial Water Purification System Capacity range between 38m3/day to 7500m3/day. If you need smaller than this capacity please see our commercial water treatment systems.

All industrial reverse osmosis water treatment systems are started from booster pump, it feeds raw water to pretreatment tanks. Depends on capacity pretreatment tank size and numbers can be changed. Also depend on raw water source and TDS (Total Dissolved Solid) material can be changed. In Chunke if water source is Tap or low TDS fresh water, we can use FRP, Stainless Steel 304 or 316. If salt content and TDS high, because of the corrosion, we are using FRP or Carbon Steel material for pretreatment tanks. Pretreatment consists of Sand Media Filter Tank, Activated Carbon Filter Media Tank and Softener Tank which has ion exchange resin inside, they are very important for reverse osmosis water filtration.

Pretreatment is used to remove large number of suspended solids, iron, turbidity, unwanted color, unpleasant taste, chlorine, sediment, organic contaminants, odors. In pretreatment we can control the flow manual or automatic for industrial water purification.

Product Show :

Function of each part of water treatment plant 1.feed water pump -- provide the pressure to quartz sand filter/active carbon filter2.Multi-medium filter-- get rid of turbidity, suspended matter, organic matter, colloid, ect.3.Active Carbon filter--Remove the color, free chloride, organic matter, harmful matter, ect. 4.Softener--exchange "ions" of calcium and magnesium with the most common and easiest method.5.Security filter--prevent large particles, bacteria, viruses into RO membrane, accuracy is 5um6.High pressure pump-- Provide the high pressure to RO membrane 7.RO system-- main part of the plant. The RO membrane's desalting rate can reach 99%, removing over 99% ions8.UV sterilizer or ozone generator--- kill bacteria

Q: Are you trading company or manufacturer ?

A: Yes, we are a manufacture with designing, manufacturing, marketing and exporting

Q: What's the information you need to know before order?

A: what's your raw water ?B: what's the capacity per hour of the equipment ?C: What's the application of purifier water ?Q:Which machine should I choose?

A:It depends on your raw water quality ,pure water requirement and the water production you needQ: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 40% T/T in advance ,60% TTbalance before shipment

Q: How long is your delivery time?

A: Generally it is 15-30 days, Depends on your project

Q:How can you control the quality and delivery?

A:All our machines will be tested before packaging. wooden packing is strong and safety for long delivery

Q:What's your warranty?

A:Our warranty is 1 year. But normally, our machine can work 5 years before repair.